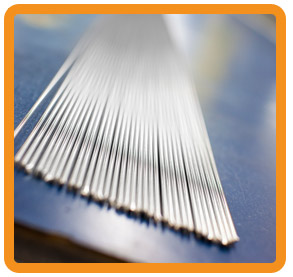

K-Tube Technologies offers customized miniature stainless steel tubing with choices ranging from size and alloy to several cutting solutions and eventually even how you want your parts delivered. After all, some applications require very specific parts! For your stainless steal tubing, K-Tube is a great partner. We can help you design your tube and take it to production.

K-Tube Technologies offers customized miniature stainless steel tubing with choices ranging from size and alloy to several cutting solutions and eventually even how you want your parts delivered. After all, some applications require very specific parts! For your stainless steal tubing, K-Tube is a great partner. We can help you design your tube and take it to production.

Find out more about the K-Tube Discover engineering program HERE

Of course, we also offer standard tubing which you can order directly from our online store.

To give you a clear idea of K-Tube’s capabilities in custom solutions, we listed all the options here below:

ALLOY CHOICES

304, 304L, 316, 316L, 321, 17-7 PH®, 430, I-625

Others available upon request.

PROCESS AND SURFACE FINISH CHOICES

- Welded and drawn

- Plug drawn/mandril drawn

- Homogenous tubing (HT)

- Surface finish requirements tailored to meet your specifications

- Ra/Rq

MECHANICAL PROPERTY CHOICES (Specify range or value)

Fully annealed to cold-worked, hard condition

- Tensile

• Yield, elongation

• Hardness: Rockwell B or C

FINISHED TUBE LENGTH CHOICES

- Coil

- Footage – up to 20 feet

- Cuts

CUT TYPE CHOICES

- Shear – closed end

- Electrolytic – 100% open end/burr free with slight radius

- Abrasive – 100% open end

- Laser – 100% open end/burr free

- Score break – 70-90% open end

CLEANING CHOICES

- Standard rinse

- Ultrasonic

- Passivation

- Flush

- Chemical

DELIVERY CHOICES

- Standard

- Expedited

- QRM – Quick Response Manufacturing

REFERENCE CHART—INDUSTRY-STANDARD GAGE SIZES

Following soon.